OUR

PRODUCTS

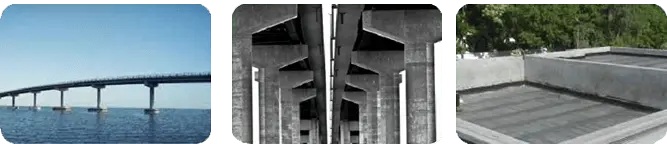

High – Strength Concrete

High-strength concrete has compressive strength greater than 40 MP and is deemed especially useful in high rise buildings/ towers/ dams and other heavy load requirements.

Advantages:

- Higher durability & Strength characteristics which ensure stronger structures

- Resists loads that cannot be resisted by normal-strength concrete

- Superior long term service performance under static, dynamic and fatigue loading

- Low creep and shrinkage

- Greater stiffness as a result of a higher modulus Elasticity

- Reduction in total steel requirements

Water Proof Concrete

Waterproof concrete, watertight ready mixed concrete or waterproofed concrete keeps water out of the concrete. Ordinary concrete contains fine pores which allow moisture to penetrate the surface and pass through. The size and volume of these pores is dictated by the water/cement ratio; the higher the ratio, the more porous the concrete

Advantages:

- No additional preparation or oil-based membrane required to make the concrete waterproof

- Lesser time and labour on site

- Better for the environment

- Less susceptible to cracking

Temperature Controlled Concrete

Advantages:

- Controls thermal cracks in concrete

- Improved durability

- Longer work ability retention

- Reduced cold joints

High Density Concrete

Advantages:

- Higher Durability

- Useful for the purpose of radiation shielding

- For steel applications where higher weight per cubic meter of concrete is required such as ballast & dead weight.

Fiber Reinforced Concrete

(Glass, Poly propylene, Polyester etc.)Concrete designed with micro or macro fibers can be used either for structural applications, where the fibers can potentially substitute for steel rebar reinforcement, or for reducing shrinkage—primarily early age shrinkage. Macro fibers can significantly increase the ductility of concrete, making it highly resistant to crack formation and propagation.

Advantages:

- Improved Flexural properties

- Reduced frequency of plastic cracking

- Higher abrasion and impact resistance

- Reduced porosity if the structure

- Cost savings through reduction in steel requirements

- Faster construction

Foam Concrete

Applications in Void Filling (eg. disused storage tanks, pipelines, sewers, tunnels, culverts, subways, mine workings, cellars and basements, underground voids and caverns, archaeological excavations, trenches, swimming pools, relining of pipes etc.), Trench Reinstatement, Road and Pavement Sub-Bases , Bridge Abutments , Construction Strengthening , Emergency works – Structural support ( eg. basements, tunnels, bridges, roads), Thermal Insulation (eg. roofing, walls, floors), Pre-cast blocks and panels.

Advantages:

- Does not settle, hence requires no compaction

- Free flowing – spreads to fill all voids

- Excellent load spreading characteristics

- Excellent fire resistant properties

- Sufficiently strong and durable for most applications

- Excellent sound and thermal insulation

- Easy to re-excavate

Stamped Concrete

Stamped concrete is concrete that has been dyed for decorative purposes.

Advantages:

- Decorative architectural concrete in flooring, wall panels etc.

- Beyond a pleasant appearance, concrete floors are also stain-resistant and easy to maintain

- Any number of texturing techniques can be applied to create patterns or “antique” effects

- Range of colour options available to suit the customer needs